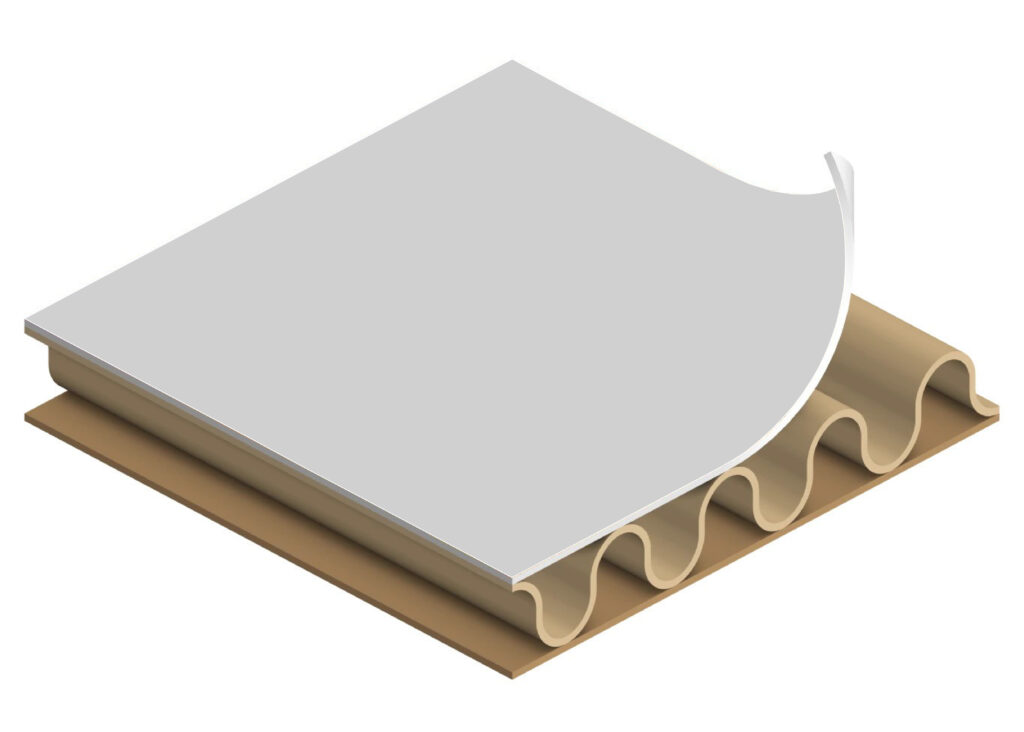

At Enhance Packaging, we utilise Fujifilm SUPERIA ZX processless thermal printing plates. This is a technical choice as much as it is a philosophical one. Processless plates are a groundbreaking technology which offers many benefits such as the time and cost savings associated with processor maintenance, space and also utility savings by completely eliminating the processor.

Importantly, environmental considerations are also vastly improved by creating a safer work environment that reduces chemical exposure.

Benefits to our customers include:

- Lower costs

- More consistent print quality and sharpness

- Faster and easier corrections or changes